1. Marking Warning Lines: Mark a warning line on the pressure gauge dial based on the equipment's maximum operating pressure. Do not apply this line to the dial glass to prevent misleading operators.

2. Inspection and Sealing: Pressure gauges that have not passed inspection and are not sealed must not be installed or used. Ensure that the pressure gauge has undergone legal inspection and is sealed.

3. Maintaining Cleanliness: The pressure gauge should be kept clean, and the dial glass should be bright and transparent to ensure clear pressure readings.

4. Regular Maintenance: The pressure gauge connection should be regularly flushed and maintained unobstructed. During vessel operation, if any abnormal pressure gauge indication is observed, such as unclear scale, cracked glass, pointer failure to return to zero, or damaged seal, it should be calibrated or replaced immediately.

5. Calibration Interval: Pressure gauge maintenance and calibration should comply with the regulations of the national metrology department. The calibration interval is generally no more than six months and is implemented in accordance with JJG 52-2013.

- Home

- About Us

- Products

- Engine Parts

- Turbocharger

- Starter Motor

- Fuel Injector

- Fuel Injection Pump

- Cylinder Head

- Alternator

- Air Compressor

- Nozzle

- Plunger

- Oil Pump

- Water Pump

- Fuel Tranfer Pump

- Electric Fuel Pump

- Cylinder Block

- Camshaft

- Crankshaft

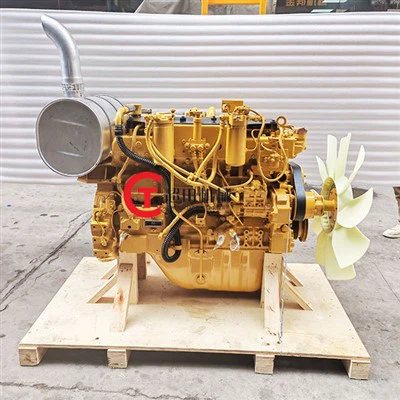

- Engine Assy

- Muffler

- Fan Blade

- Oil Cooler

- Oil Cooler Cover

- Valve Chamber Cover

- Intake&Exhaust Manifold

- High Pressure Pipe

- Other Engine Parts

- Electric Parts

- Engine Overhaul Kit

- Hydraulic Parts

- Undercarriage Parts

- Seal Kit

- Filter and Radiator

- Tool and Machines

- Engine Parts

- News

- Blog

- Contact Us

- Article

- Request a Quote