Bearings are primarily classified into rolling bearings and plain bearings. Rolling bearings utilize steel balls or rollers to reduce friction, resulting in a coefficient of friction as low as 0.001-0.005, making them suitable for high-speed rotation. Examples include deep groove ball bearings (maximum speed 10,000 rpm) and tapered roller bearings (contact angle 10°-30°). Plain bearings rely on a lubricating film, resulting in a coefficient of friction of approximately 0.01-0.1, making them suitable for heavy-load, low-speed applications, such as marine engines. Deep groove ball bearings feature continuous grooves in the inner and outer rings, with the balls evenly distributed within a cage. They can achieve a dynamic load rating of up to 14 kN (e.g., 6205 bearings), and a service life formula of L10 = (C/P)^3. When selecting a bearing, consider the load direction, speed (angular contact bearings are suitable for speeds above 20,000 rpm), and environmental conditions (corrosive environments require stainless steel bearings).

- Home

- About Us

- Products

- Engine Parts

- Turbocharger

- Starter Motor

- Fuel Injector

- Fuel Injection Pump

- Cylinder Head

- Alternator

- Air Compressor

- Nozzle

- Plunger

- Oil Pump

- Water Pump

- Fuel Tranfer Pump

- Electric Fuel Pump

- Cylinder Block

- Camshaft

- Crankshaft

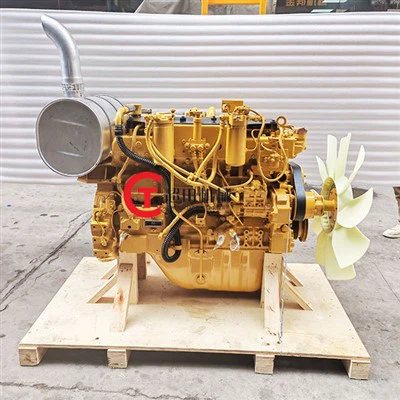

- Engine Assy

- Muffler

- Fan Blade

- Oil Cooler

- Oil Cooler Cover

- Valve Chamber Cover

- Intake&Exhaust Manifold

- High Pressure Pipe

- Other Engine Parts

- Electric Parts

- Engine Overhaul Kit

- Hydraulic Parts

- Undercarriage Parts

- Seal Kit

- Filter and Radiator

- Tool and Machines

- Engine Parts

- News

- Blog

- Contact Us

- Article

- Request a Quote